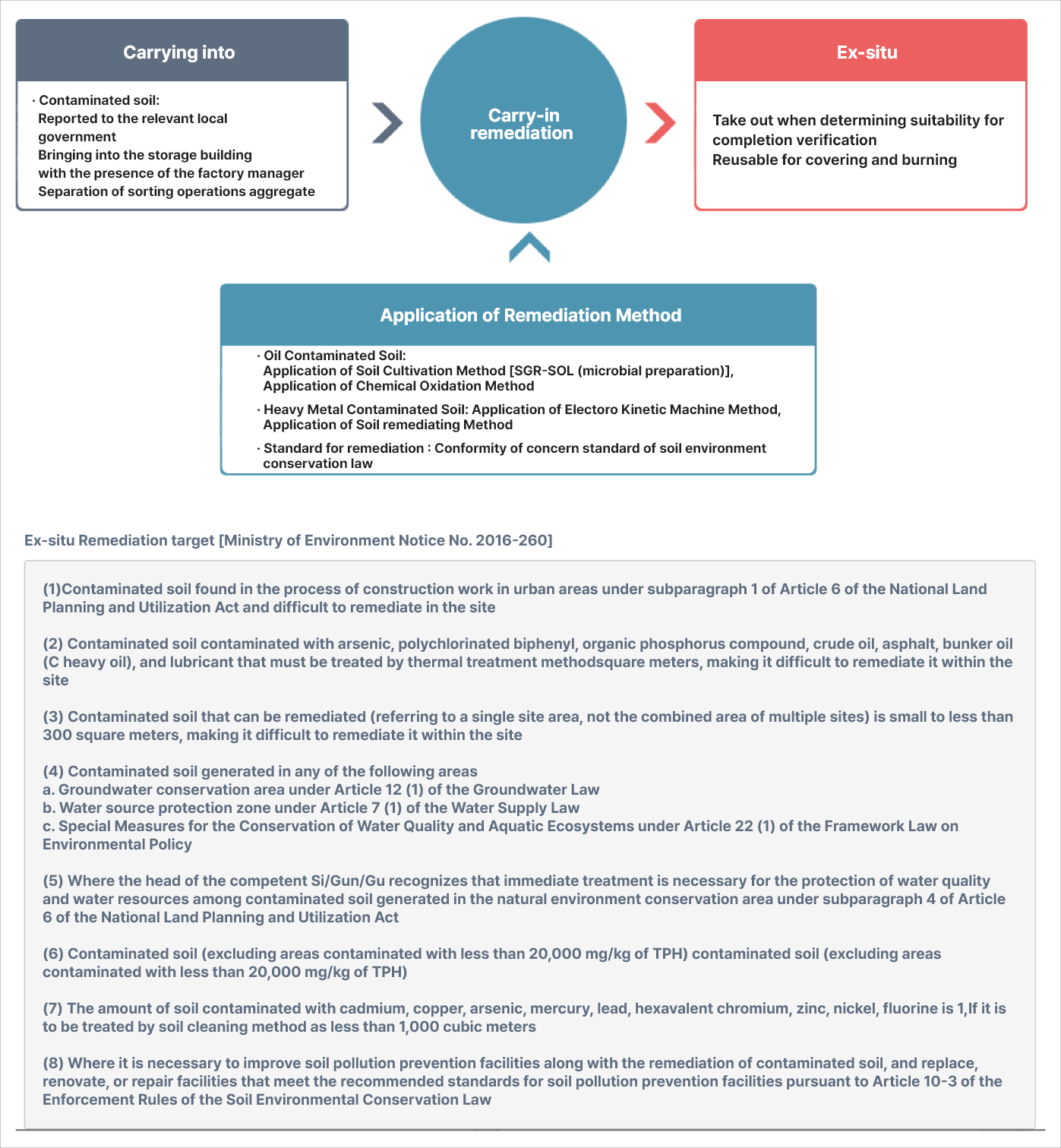

Ex-Situ

Ex-situ Remediation

The method of either landfarming soil excavation or transporting it to off-site remediation facility for remediation.

- Advantages

-

- • No need to consider the geological structure of the soil

- • Ease of adjusting the driving factor

- • Processing period is short

- • Can be handled in case of high concentration contamination

- Disadvantages

-

- • High cost of treatment such as soil excavation cost

- • Ground environment disturbance as contaminated soil is excavated from the site

- • Removal of contaminated soil and exposure of contaminants during movement

Public law and company-owned technology

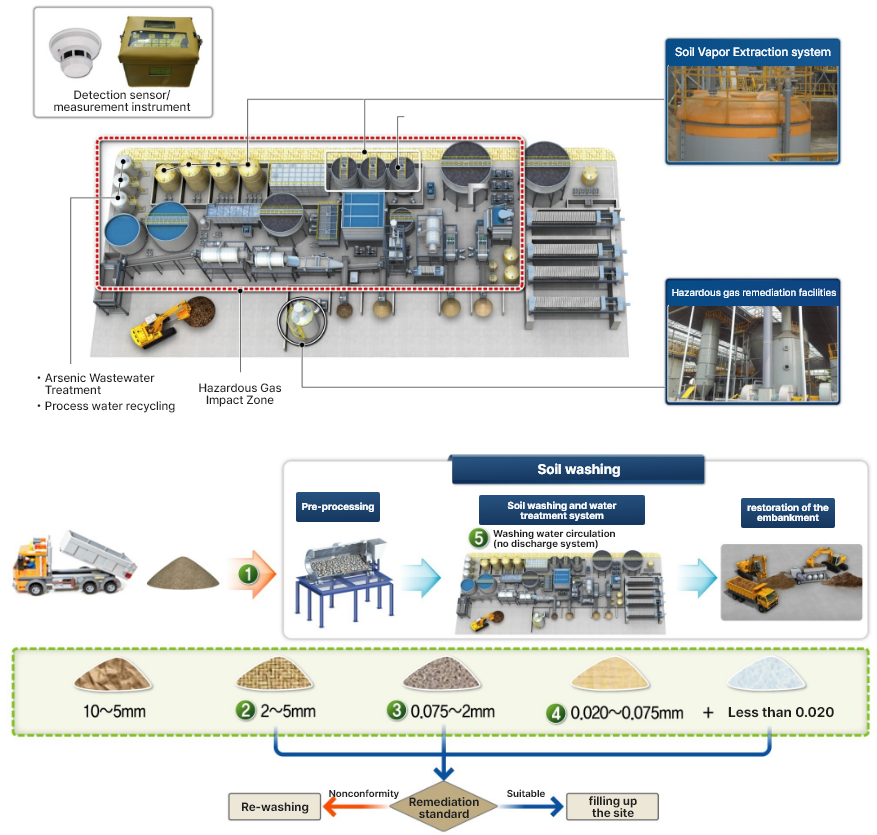

Soil Washing

Technical Overview

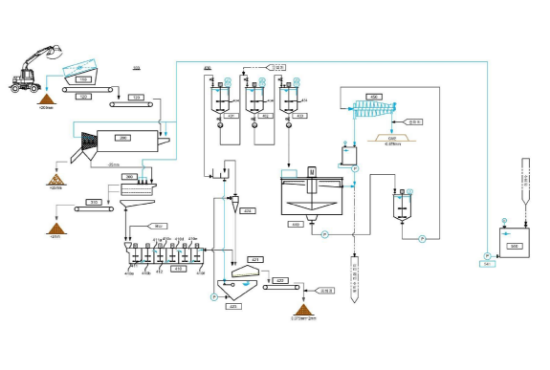

Technology to separate and treat harmful organic or inorganic contaminants bound to soil particles by combining physical screening and chemical elution processes using cleaning agents.

Technology Status

- • Method of desorbing and purifying pollutants attached to soil particles

- • Proven track record in the soil washing and remediation of heavy metal and hydrocarbon-contaminated soils.

- • Equipped with washing facilities - fixed capacity (40 m³/hr), mobile capacity (25 m³/hr)

- • In the case of heavy metal contamination, installing a multi-stage leaching system to enhance remediation efficiency

Soil washing process schematic diagram

Detailed configuration of our specialized elevation selection

-

• Experience in the construction of the largest heavy metal contamination site in Korea

- 00 Smelter Co-opted a 20 billion won clean-up project - • Specialization in the operation of washing process

- • Holding numerous patents in new technologies and washing process

2nd Off site Remediation Facility (Gyeongju) – Appearance of Soil Washing Equipment

Patents and new technologies

Chemical Oxidation

Technical Overview

A method of soil remediation that rapidly and completely decomposes soil contaminants using chemical oxidation agents.

oxidizing agent

Persulfate (PDS) (Details)

Field Application

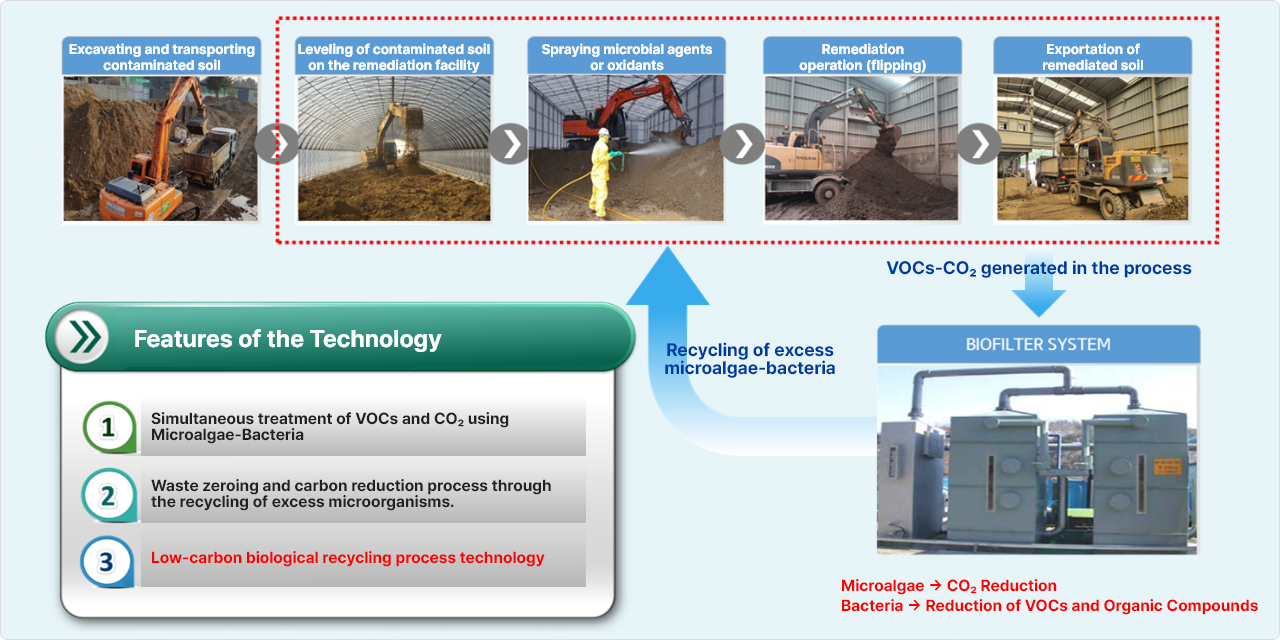

Land Farming

Technical Overview

A method for bioremediation of petroleum-contaminated soil, enhancing the activity of hydrocarbon-degrading microorganisms (aerobic) by adding air and nutrients to reduce petroleum contaminants through microbial degradation.

Land farming advantages and disadvantages

- Advantages

-

- • Easy to manage installation and remediation processes

- • Effective control of concentration of contaminated soil

- • Efficient treatment of oil-based hydrocarbon contaminants

- Disadvantages

-

- • Requires a lot of space (separate remediation processing facility required)

- • For volatile organic compounds, reduction occurs through volatilization rather than biodegradation (separate exhaust gas treatment facility required)

- • Not suitable for high concentrations (50,000 ppm or more) of hydrocarbon and heavy metal contamination

Land farming operating procedures

-

Soil contamination import operation

-

Microbial dispersion

-

Spraying water and nutrient solution

-

Tilling operations

-

Monitoring (process verification)

-

Soil sampling for completion verification

-

Analysis (complete verification)

-

Export of remediated soil

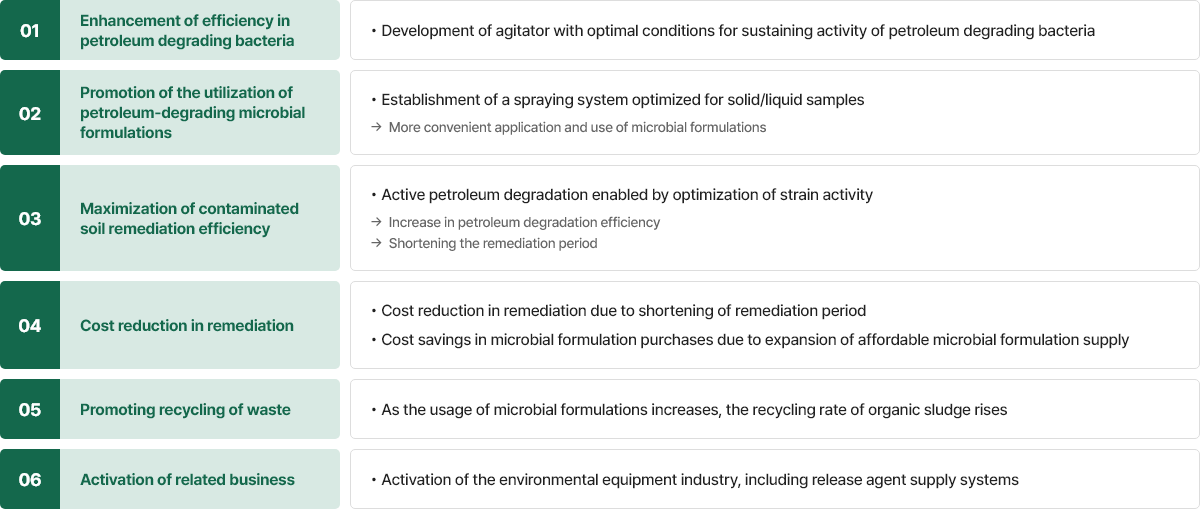

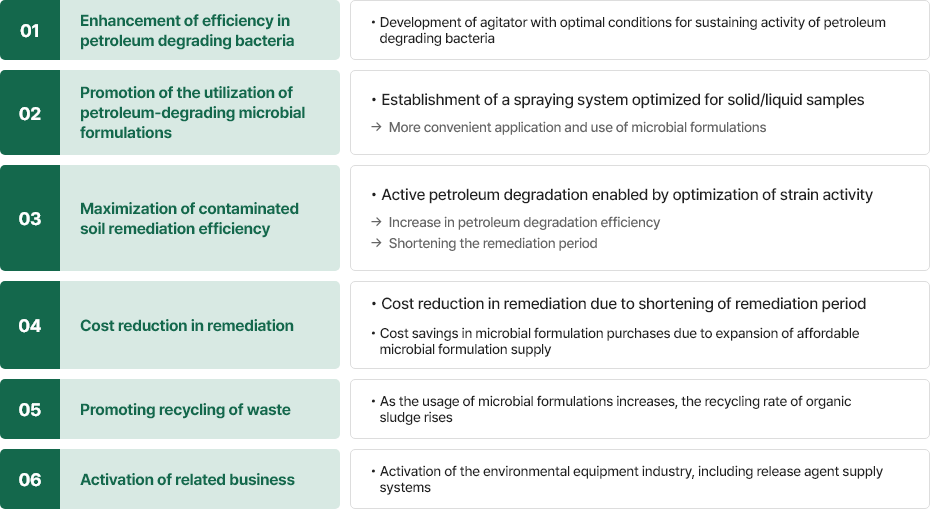

SGR technology : ① Land farming utilizing our own microbial formulation

Technology Status

- • Owns resource-circulating microbial formulation production technology using sewage sludge (Patent registered)

- • Owns soil remediation method utilizing in-house produced microbial formulation for petroleum contaminated soil

- • Owns performance of on-site application of in-house produced microbes at the off-site remediation facility

- • Owns performance of third-party supply for in-house produced microbial formulations (Contaminated soil remediation project for Unit 00)

- • Expect cost savings compared to conventional land farming methods

Patent (No. 10-0947348)

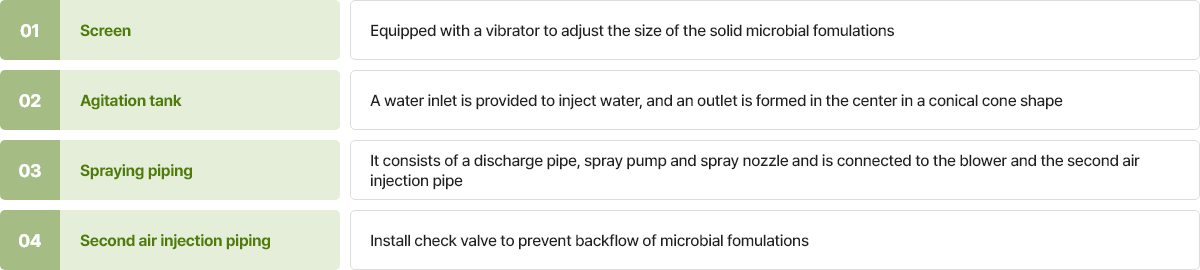

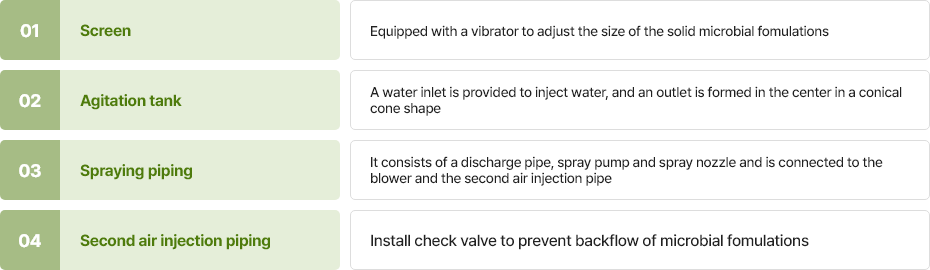

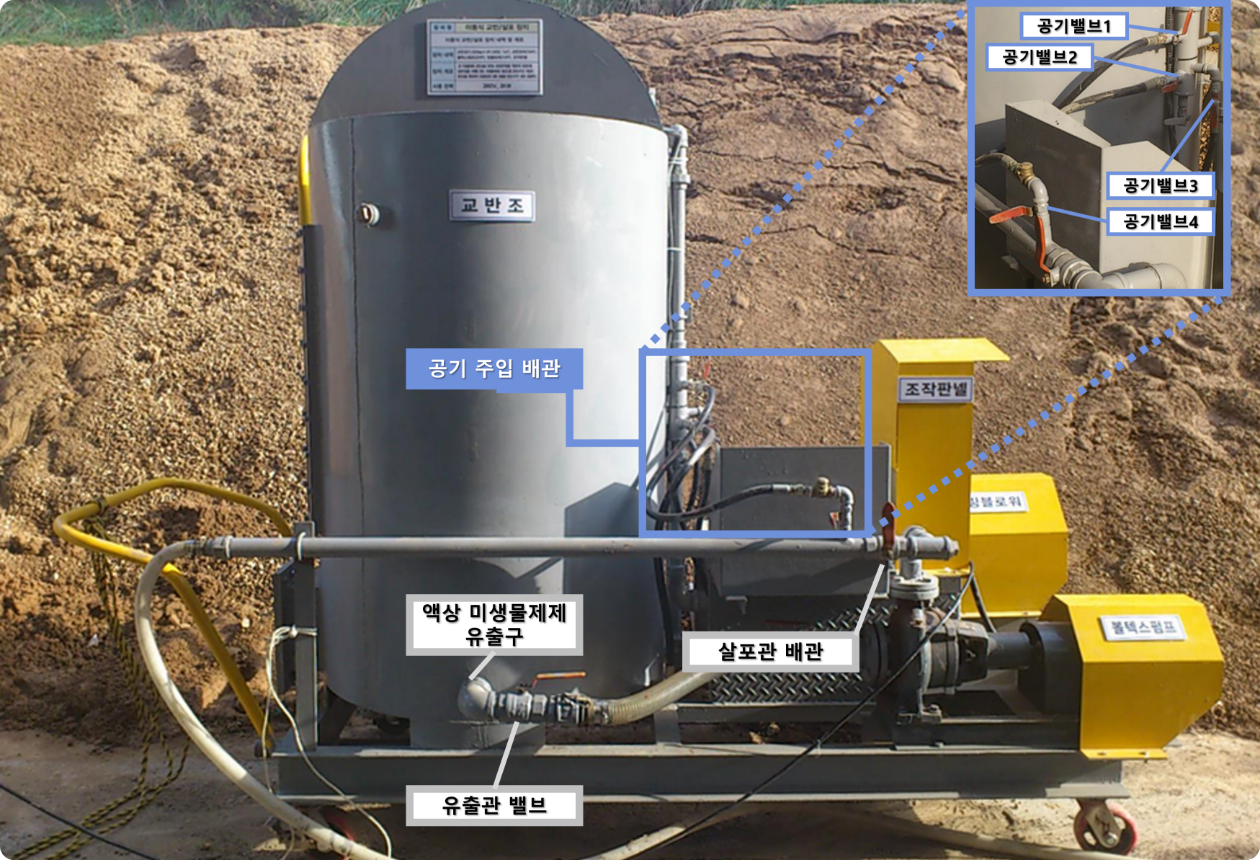

SGR technology : ② Its microbial injection equipment

Used for the effective spraying of microbial during Land Farming operations

Equipment Configuration

Microbial injection equipment

Patent (No. 10-1165675)

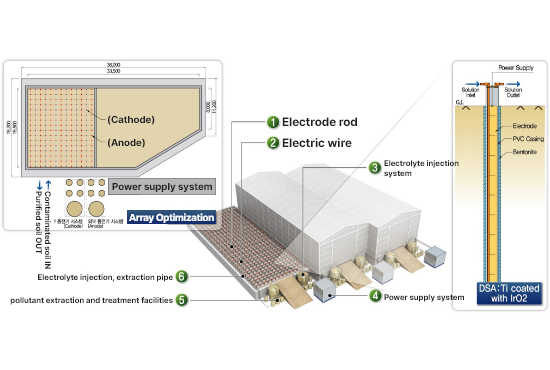

Electro Kinetic

Technical Overview

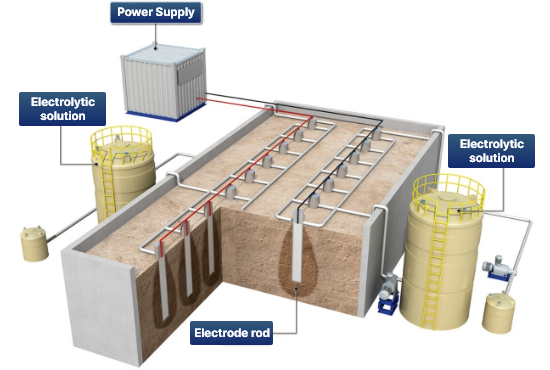

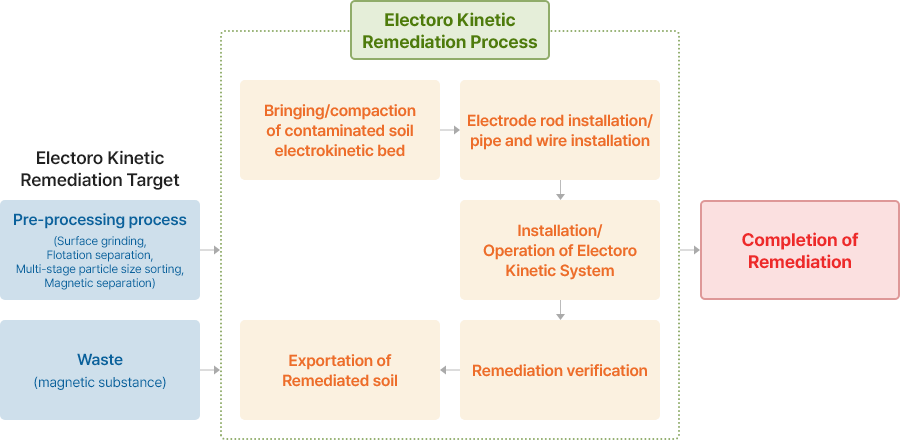

After installing an electrokinetic bed in contaminated soil with homogeneous particles, applying current through electrode rods induces physicochemical and hydraulic changes in the subsurface, extracting and removing contaminants through the phenomenon of electroconduction.

Technology Status

- • Effective application to fine-grained ground with low water permeability

- • The capacity of the electrokinetic bed determines the batch size

- • Although the treatment period is somewhat longer compared to soil washing methods, it exhibits excellent separation effects of pollutants, and remediation costs are reduced.

- • We possess extensive experience in remediation projects. (OO smelter contaminated soil remediation project, etc.)

Flowchart of galvanic purification process

Field Application : Electrokinetic System Installation

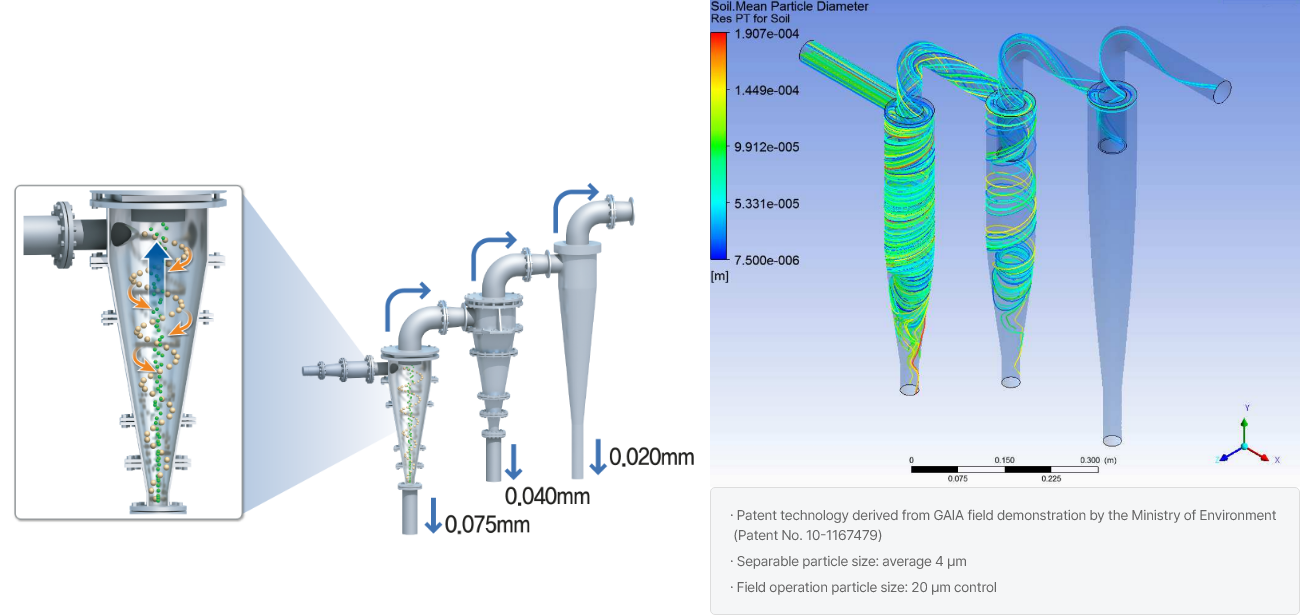

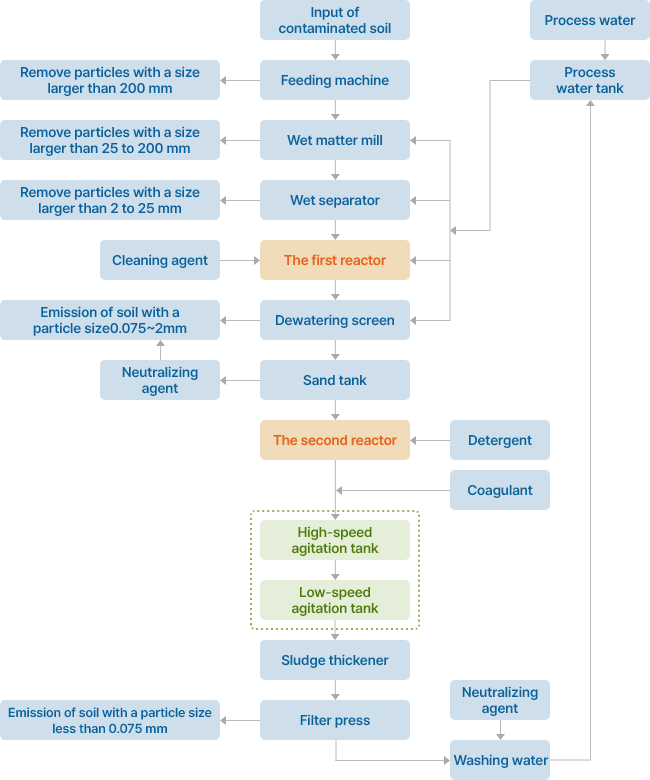

Heavy metal contaminated soil remediation technology

Technology Status

- • Efficiently remediate soil contaminated with heavy metals by differentially separating it based on contamination concentrations and particle sizes. Sequentially remove heavy metals according to optimal reaction conditions.

- • When washing contaminated soil, the wash water used is also remediated, enabling its reuse in the process canal.

Patent (No. 10-13 7106)

Process chart

Sediment Processing Unit

Technical Overview

- • A processing apparatus for effectively removing organic pollutants and odors by classifying and washing dredged soil from river and stream beds based on particle size.

- • It incorporates a belt conveyor to prevent congestion during sediment transport and utilizes a rotary valve to enhance the efficiency of sediment utilization.

- • It processes recyclable dredged soil through size-based washing and dewatering.

Patent (No. 10-13 7106)

Carbon-Reducing Technology

Technical Overview

- • Simultaneous reduction of VOCs and CO2 generated during petroleum-contaminated soil remediation using microalgae-bacteria co-culture.

- • Waste zeroing process through the recycling of excess microorganisms (Microalgae-Bacteria)